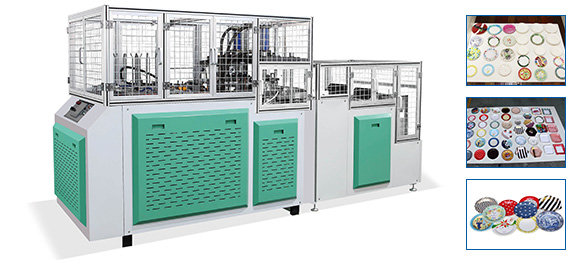

High Speed Double Lane Paper Plate Making Machine uses desktop layout, which isolates the transmission parts and molds. The transmission parts are under the desk, molds are on the desk, this layout is convenient for cleaning and maintenance. The machine adopts automatic lubrication, mechanical transmission, hydraulic forming and pneumatic blowing paper, which has the advantages of stable performance and easy operation & maintenance. For electrical parts,PLC, photoelectric tracking, machine with cover for protection, auto intelligent & safe fabrication, can directly support production line.

Technical Parameter

| Main Technical Parameters |

| Paper Plate Size |

4-13” |

| Paper Grams |

100-800g/m2 |

| Paper Materials |

Base paper, whiteboard paper, white cardboard, aluminum foil paper or others |

| Capacity |

Double Stations 40-110pcs/min |

| Power Requirements |

380V 50HZ |

| Total Power |

8KW |

| Weight |

1600kg |

| Specifications |

3700×1200×2000mm |

| Air Supply Requirement |

0.4Mpa, 0.3cube/min |

| Other Notes |

Customize |

| Oil Cylinder |

ML-63-150-5T-X |

| Cylinder Stroke |

150mm |

Advantage & Improvement

1. independent research and development, the latest products, using the fast oil pressure system, each station is 15 – 20 minutes faster than ordinary machine

2.send paper using mechanical work, stable performance. Compared to the ordinary type of paper drop technology, the waste rate is greatly reduced to 1/1000

3.can be directly with the packaging machine (paper disc packaging labeling machine (film), good packaging and labeling). Suitable for production. Machine with PLC.

4.can automatically produce all kinds of non-standard products, finished product rate of one hundred percent, solved the problem of ordinary machines can not complete

5.hydraulic oil recycling, reduce emission pollution, low noise.